Published - 21st Mar 2025

Components for performance critical applications from Metaltech Precision

Metaltech Precision is proud to announce successful certification in ISO 3834 and EN 15805, demonstrating the high quality and reliability of our welding expertise. These accreditations build on our existing Triple ISO certifications to show our commitment to delivering quality-assured solutions that customers can trust.

Welding is considered a ‘special process’, which means that its quality cannot be readily verified without destroying the weld. The quality of welding is instead judged by qualifying the procedure, the equipment and the people who will be making the weld.

Successful certification at ISO 3834 for high quality welded components therefore requires specialist management, personnel and procedures above and beyond those that are considered for general quality systems such as ISO 9001.

Metaltech Precision is proud to have been awarded ISO 3834 certification. ISO 3834 sets the highest standard for delivering complex, demanding and mission-critical welded fabrications for sectors such as aerospace and defence.

Our expertise in high quality welding fabrications includes defence applications such as submarine trolley and land vehicle fabrications. Compliance to this standard demonstrates our commitment to high quality welded components, continuous improvement, and meeting our customers’ needs.

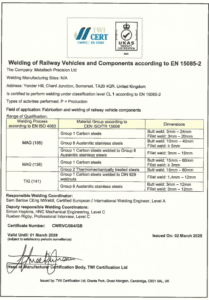

Welding is an important process in the production of railway vehicles components and sub-assemblies. EN 15085 certification was introduced to ensure that the design, production, and testing of welded components are complete to a regulated quality.

Metaltech Precision’s highly accredited welding team now holds EN 15085 certification, confirming the high quality of our welded components. We are now one of very few manufacturing companies in the UK who have achieved this certification, most of whom are OEMs.

Customers benefit from our high level accreditations in EN 15805 and ISO 3834 in a number of ways:

These certifications demonstrate that Metaltech Precision meets internationally recognised standards for welding operations, particularly in the rail and Defence industries. This ensures consistent, high-quality production of welded metal products and components.

EN 15085 promotes safe working behaviours and equipment operation, leading to fewer accidents and errors, which ultimately results in safer end products for customers.

These certifications can lead to improvements in process efficiency, reducing production times and potentially lowering costs for customers.

EN 15085 is recognised worldwide as the gold standard in rail industry certification, allowing our customers in international supply chains to rely on Metaltech Precision for precision welding for global contracts.

Many customers, especially in the rail and Defence sectors, now require these certifications from their suppliers to ensure that contractors are working to the highest standards.

Achieving EN 15805 and ISO 3834 certifications ensures that Metaltech Precision keeps abreast of specialised technical knowledge, benefiting our sister companies in Expromet Technologies Group and by extension, our customers.

These certifications provide independent confirmation of Metaltech Precision’s welding capacity, competence, and employee capabilities. EN 15085 is recognised worldwide as the gold standard in rail industry certification, inspiring customer confidence in our ability to meet global standards.

ISO 3834 works in tandem with other quality management systems like ISO 9001, ensuring a holistic approach to quality control.

The standards are designed to safeguard the quality of manufacturing and the accuracy of components’ performance, driving reliability and environmental protection.

As a certified company, we are better equipped to manage and reduce risks associated with welding processes, providing customers with more reliable products and services.

Metaltech Precision offers extensive in-house fabrication facilities, including 25 tonne overhead cranage, providing a one stop shop for your fabricated and machined components and assemblies.

Our welders are fully coded in MIG and TIG to the latest ISO/ASME standards, and as a company we hold accreditations in ISO 14001, BS OHSAS 18001, ISO 45001, AS9100 Rev D and ISO 9001: 2015. By achieving these new certifications in EN 15805 and ISO 3834 Metaltech Precision successfully demonstrates effective control of weld quality through proper management throughout our systems.

Find out more about welding and fabrication from Metaltech Precision: contact us now!

If you have a project, talk to our experienced sales team

Contact us